Metal forging

At Deruijin, whether it is hot forging, die casting, or precision forging, Deregin can achieve it all.

Derui Jin uses high standard materials for forging products, ensuring material stability during the forming process, and ensuring the dimensional requirements and consistency of the forged products. Plus, we have kept you safe with a customized design and production option as it is always about you!

ADVANTAGE COMPARISON

TS-16949 Certified

Products Material Standard: ISO, GB, ASTM, SAE, EN, DIN, JIS, BS

Product weight range: From 0.5 kg to 10 kg

2D & 3D Drawings (Igs, PDF, JPEG, DWG, CAXA, UG, Stp, etc.) could be made and provided based on the samples.

Casting Processes include Hot forging, Cold forging, Die forging, etc

OEM and ODM service

Further Production Processes include Deburring,Sandblasting, Machining, Heat Treatment, Surface treatment, etc.

Available software: Pro/E, Auto CAD, Solid work,UG

Customization Available

Mould life: usually 50,000 shots

Mould material: Cr12, 4Cr5MoSiV1, 4Cr5MoSiV, etc

ADVANTAGE COMPARISON

TS-16949 Certified

Products Material Standard: ISO, GB, ASTM, SAE, EN, DIN, JIS, BS

Product weight range: From 0.5 kg to 10 kg

2D & 3D Drawings (Igs, PDF, JPEG, DWG, CAXA, UG, Stp, etc.) could be made and provided based on the samples.

Casting Processes include Hot forging, Cold forging, Die forging, etc

OEM and ODM service

Further Production Processes include Deburring,Sandblasting, Machining, Heat Treatment, Surface treatment, etc.

Available software: Pro/E, Auto CAD, Solid work,UG

Customization Available

Mould life: usually 50,000 shots

Mould material: Cr12, 4Cr5MoSiV1, 4Cr5MoSiV, etc

Metal forging

Professional processing and manufacturing sheet metal molds, plastic molds, blowing molds, forging molds, precision parts, operating mold materials and mold accessories and related plastic punching products.

1. Equipment: Laser Cutting Machine, Bending Machine, Punching, Nibbling Machine, Press Machine, CNC, Lathe machine, Milling machine, Drilling machine, Grinding machine, and so on;

2. Heat Treatment: annealing , carbonization, tempering, quench, normalization and surface tempering

3. Surface treatment: Powder coating, Anodization, Chrome plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, etc.

Tooling & Mould:

1. Mould life: usually semi-permanent.

2. Tooling Leadtime: 15-25 days, depending on the structure and size.

3. Tooling & mould maintenance: Be responsible by Deruijin.

Quality control:

1. Quality control: The defective products rate is less 0.1%.

2. Sample and pilot run will be given 100% inspection during production and before shipment, Sample check for mass production according to ISDO standard or customer requirements

3. Test equipment: Spectrum Analyzer, CMM, Hardness test equipment, Tension test machine;

4. After-sales services are available.

5. Quality situation can be traceable.

– Carbon Steel: 10#, 15#, 20#, 25#, 30#, 35#, 40#, 45#, 50#, 55#…etc.

– Alloy Steel: 15Mn, 16Mn, 40Cr, 42CrMo…and other alloy steel.

– Stainless Steel: SUS304, SUS316, SUS316L, etc

– Aluminum: 6061 T6, 6063 T6

1. OEM & ODM both accepted. Products can be designed and produced as per customer’s requirements in forms of Samples, Drawings or even just a draft idea.

2. Over 20 years of experience in casting, welding, forging and precision machining for US, European and other overseas markets.

3. Leadtime (Negotiable) :

– For toolings: around 15-35 days.

– For samples: 7- 15 days.

– For batch production: 25 days.

4. Payment terms (Negotiable):

– For toolings: 100% pre-payment before development.

– For samples: For free unless the sample(s) value is too big.

– For mass production: 30% down payment before production (and after samples approval), balance 70% before delivery.

5. Package: Carton Box, PlyWood Box, Standard Export Pallets or as per customers’ requirements.

6. Shipping terms: EXW, FOB, CFR, CIF, DDP, DDU…all could be accepted.

WE STRIVE TO LEAD THE INDUSTRY WITH PERFECTLY PRECISE ENGINEERING SOLUTIONS

Material Available:

– Carbon Steel: 10#, 15#, 20#, 25#, 30#, 35#, 40#, 45#, 50#, 55…etc.

– Alloy Steel: 15Mn, 40Cr, 42CrMo…and other alloy steel.

– Stainless Steel: SUS304, SUS316, SUS316L, SUS410…etc.

– Ductile Iron: QT400, QT450, QT500, QT600, QT700, QT800, and GGG40, GGG50, GGG60, GGG70, GGG80, etc.

– Grey iron: HT100, HT150, HT200, HT250, HT300, HT350 and GG15, GG20, GG25, GG30, GG35, GG40.

– Other Material:Cast Iron, Steel, Aluminum, Brass, Alloys or as per customer requirements, etc.

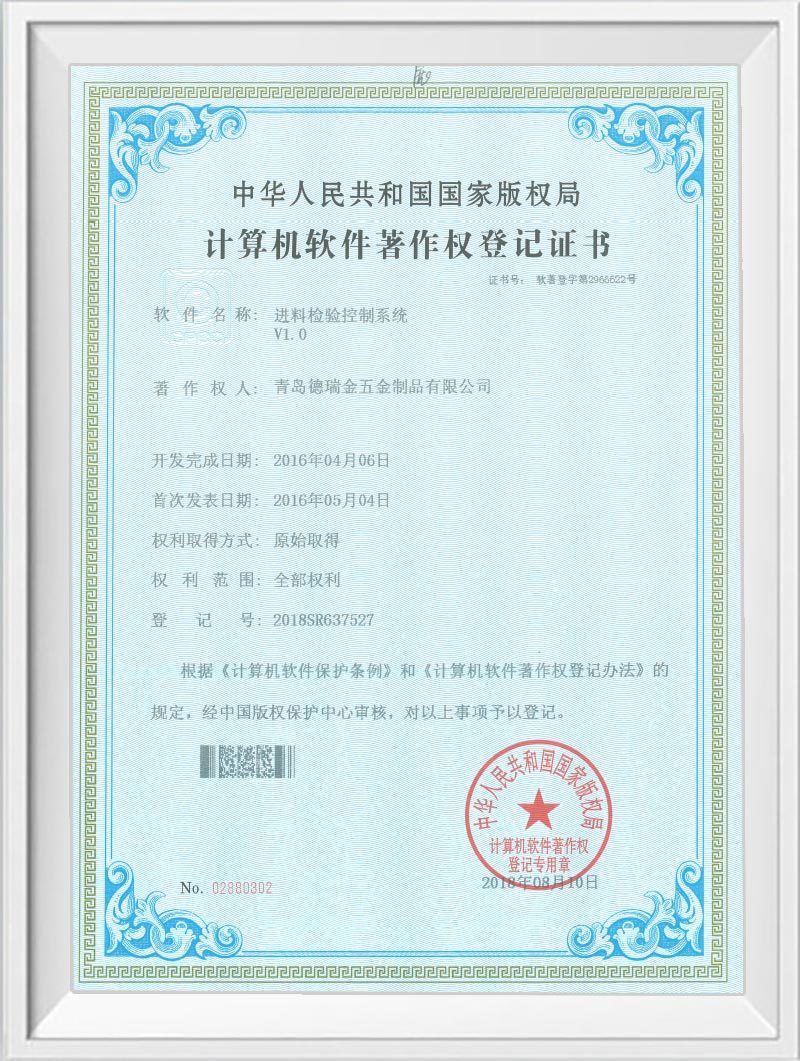

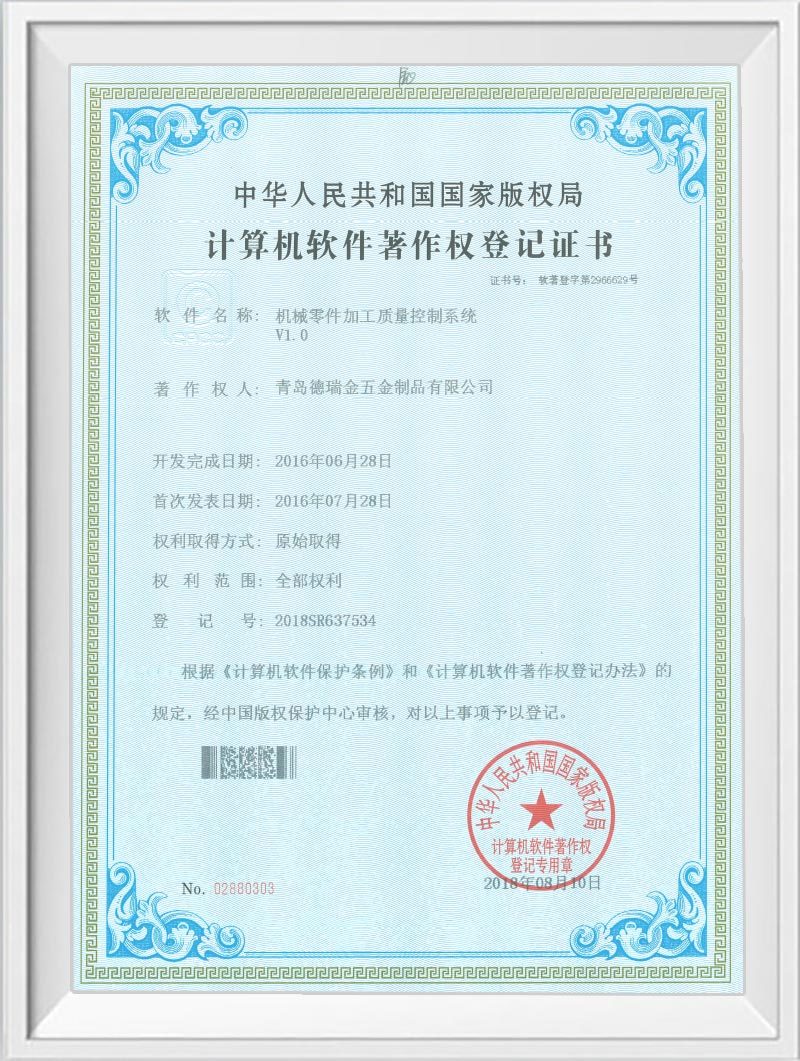

Honor

At Deruijin, you would not struggle to find anything! You can customize any stamping product you need. We have various specifications of punching machines, ranging from 20T-500T, with over 50 stamping equipment. We have our own mold design team, which can design and manufacture molds according to your needs, and provide free mold maintenance services.

Utility model patent certificate

Utility model patent certificate

Trademark registration certificate

Honors

Honors

Computer software copyright registration certificate

Computer software copyright registration certificate

Computer software copyright registration certificate

Computer software copyright registration certificate

Computer software copyright registration certificate

Computer software copyright registration certificate

Computer software copyright registration certificate